Magico Q-Pod

Magico Q-Pod

Throughout the development process of the Q platform numerous advances in the area of resonance management were made.

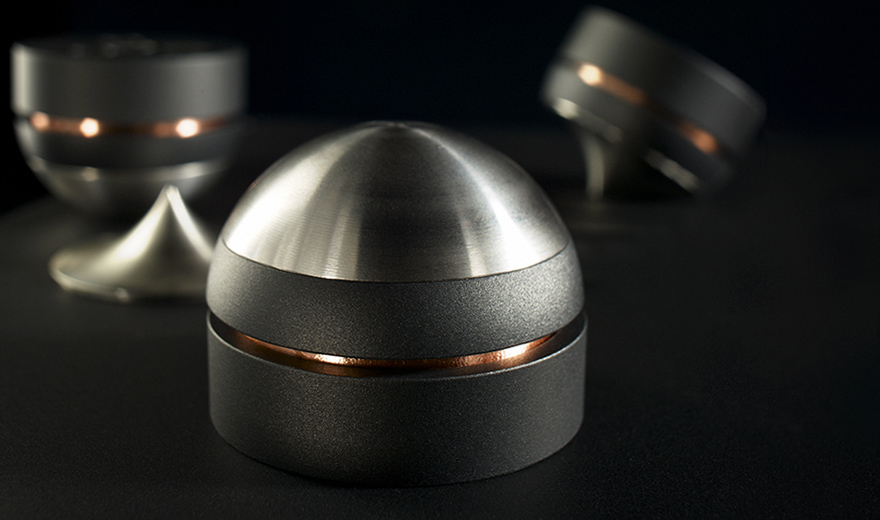

Originally developed for internal R&D, Magico is introducing the QPods to maximize front-end system performance. The pods themselves are CNC-turned and milled from hardened stainless-steel, oxygen-free copper, and hard black-anodized aircraft-grade aluminum. These materials create the constraining layers for the damping material that is alternately clamped between to create a single traverse dissipating unit, which we call the QPod.

QPod

Throughout the development process of the Q platform numerous advances in the area of resonance management were made.

Originally developed for internal R&D, Magico is introducing the QPods to maximize front-end system performance. The pods themselves are CNC-turned and milled from hardened stainless-steel, oxygen-free copper, and hard black-anodized aircraft-grade aluminum. These materials create the constraining layers for the damping material that is alternately clamped between to create a single traverse dissipating unit, which we call the QPod.

Vibrational wave propagation through the floor, stands, and the equipment itself is converted into heat energy through the side-to-side movement (known as “shear deformation”) within each layer of the pod.

By adding a multi-leveled constraining layer mechanism to equipment standoffs, electrical and mechanical vibration-induced artifacts are acutely reduced, ultimately resulting in marked improvements to signal fidelity.